Production Technology: Plain pipe-end upsetting- Austenite treatment-Quenching-Tempering-straightening-(Non-Destructive Testing)- Threading-Thread inspection-coupling MPI-phosphating-Coupling make up-Drifting-Hydrostatic testing-Measuring&Weight-Marking&Stenciling-Coating-Packing Casing and tubing-Transportation

Executive Standards: API Spec 5CT, API Spec 5B

Specification Range: 4-1/2″, 5″, 5-1/2″, 6-5/8″, 7″, 7-5/8″, 8-5/8″,9-5/8″,10-3/4″, 11-3/4″, 13-3/8″, 16″, 18-5/8″, 20″ WT: 5.21-16.13mm

Materials: J55, K55, N80, L80, C90,T95, P110 and Q125

T&C: STC, LTC, BTC, XC and Premium connection

Length: R1, R2, R3

Testing: NDT etc related rules of API 5CT and 5B

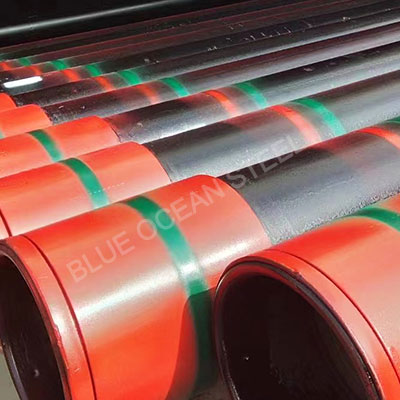

Packing: By bundles, seaworthy packing.

Application: Casing Pipe is widely used for fastening oil and gas well wall or borehold, with bigger diameter than tubing, including surface casings, technical casings and oil layer casings.

Technical Parameters of Casing Pipe

| Sizes | ODD (mm) |

Weight (kg/m) |

WT (mm) |

Type of End | ||||||||

| H40 | J55 K55 | M65 | L80 C95 | N80 1, Q | C90 T95 | P110 | Q125 | |||||

| 1 | 2 | |||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 |

9.50 10.50 11.60 13.50 15.10 |

114.30 114.30 114.30 114.30 114.30 |

14.14 15.63 17.26 20.09 22.47 |

5.21 5.69 6.35 7.37 8.56 |

PS – – – – |

PS PSB PSLB – – |

PS PSB PLB PLB – |

– – PLB PLB – |

– – PLB PLB – |

– – PLB PLB – |

– – PLB PLB PLB |

– – – – PLB |

| 5 5 5 5 5 5 5 |

11.50 13.00 15.00 18.00 21.40 23.20 24.10 |

127.00 127.00 127.00 127.00 127.00 127.00 127.00 |

17.11 19.35 22.32 26.79 31.85 34.53 35.86 |

5.59 6.43 7.52 9.19 11.10 12.14 12.70 |

– – – – – – – |

PS PSLB PSLBE – – – – |

PS PSLB PLB PLB PLB – – |

– – PLBE PLBE PLB PLB PLB |

– – PLBE PLBE PLB PLB PLB |

– – PLBE PLBE PLB PLB PLB |

– – PLBE PLBE PLB PLB PLB |

– – – PLBE PLB PLB PLB |

| Sizes | ODD (mm) |

Weight (kg/m) |

WT (mm) |

Type of End | ||||||||

| H40 | J55 K55 | M65 | L80 C95 | N80 1, Q | C90 T95 | P110 | Q125 | |||||

| 1 | 2 | |||||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 |

14.00 15.50 17.00 20.00 23.00 26.80 29.70 32.60 35.30 38.00 40.50 43.10 |

139.70 139.70 139.70 139.70 139.70 139.70 139.70 139.70 139.70 139.70 139.70 139.70 |

20.83 23.07 25.30 29.76 34.23 39.88 44.20 48.51 52.53 56.55 60.27 64.14 |

6.20 6.98 7.72 9.17 10.54 12.70 14.27 15.88 17.45 19.05 20.62 22.22 |

PS – – – – – – – – – – – |

PS PSLBE PSLBE – – – – – – – – – |

PS PSLB PLB PLB PLB – – – – – – – |

– – PLBE PLBE PLBE – – – – – – – |

– – PLBE PLBE PLBE – – – – – – – |

– – PLBE PLBE PLBE P P P P P P P |

– – PLBE PLBE PLBE – – – – – – – |

– – – – PLBE – – – – – – – |

| 6-5/8 6-5/8 6-5/8 6-5/8 |

20.00 24.00 28.00 32.00 |

168.28 168.28 168.28 168.28 |

29.76 35.72 41.67 47.62 |

7.32 8.94 10.59 12.06 |

PS – – – |

PSLB PSLBE – – |

PSLB PLB PLB – |

– PLBE PLBE PLBE |

– PLBE PLBE PLBE |

– PLBE PLBE PLBE |

– PLBE PLBE PLBE |

– – – PLBE |

| 7 7 7 7 7 7 7 |

17.00 20.00 23.00 26.00 29.00 32.00 35.00 |

177.80 177.80 177.80 177.80 177.80 177.80 177.80 |

25.30 29.76 34.23 38.69 43.16 47.62 52.09 |

5.87 6.91 8.05 9.19 10.36 11.51 12.65 |

PS PS – – – – – |

– PS PSLBE PSLBE – – – |

– PS PLB PLB PLB PLB – |

– – PLBE PLBE PLBE PLBE PLBE |

– – PLBE PLBE PLBE PLBE PLBE |

– – PLBE PLBE PLBE PLBE PLBE |

– – – PLBE PLBE PLBE PLBE |

– – – – – – PLBE |

| 7 7 7 7 7 7 |

38.00 42.70 46.40 50.10 53.60 57.10 |

177.80 177.80 177.80 177.80 177.80 177.80 |

56.55 63.54 69.05 74.56 79.77 84.97 |

13.72 15.88 17.45 19.05 20.62 22.22 |

– – – – – – |

– – – – – – |

– – – – – – |

PLBE – – – – – |

PLBE – – – – – |

PLBE P P P P P |

PLBE – – – – – |

PLBE – – – – – |

| 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 |

24.00 26.40 29.70 33.70 39.00 42.80 45.30 47.10 51.20 55.30 |

193.68 193.68 193.68 193.68 193.68 193.68 193.68 193.68 193.68 193.68 |

35.72 39.29 44.20 50.15 58.04 63.69 67.41 70.09 76.19 82.30 |

7.62 8.33 9.52 10.92 12.70 14.27 15.11 15.88 17.45 19.05 |

PS – – – – – – – – – |

– PSLBE – – – – – – – – |

– PSLB PLB PLB – – – – – – |

– PLBE PLBE PLBE PLBE PLB PLB PLB – – |

– PLBE PLBE PLBE PLBE PLB PLB PLB – – |

– PLBE PLBE PLBE PLBE PLB PLB PLB P P |

– – PLBE PLBE PLBE PLB PLB PLB – – |

– – – – PLBE PLB PLB PLB – – |

| 7-3/4 | 46.10 | 196.85 | 68.60 | 15.11 | – | – | – | P | P | P | P | P |

| 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 |

24.00 28.00 32.00 36.00 40.00 44.00 49.00 |

219.08 219.08 219.08 219.08 219.08 219.08 219.08 |

35.72 41.67 47.62 53.57 59.53 65.48 72.92 |

6.71 7.72 8.94 10.16 11.43 12.70 14.15 |

– PS PS – – – – |

PS – PSLBE PSLBE – – – |

PS PS PSLB PSLB PLB – – |

– – – PLBE PLBE PLBE PLBE |

– – – PLBE PLBE PLBE PLBE |

– – – PLBE PLBE PLBE PLBE |

– – – – PLBE PLBE PLBE |

– – – – – PLBE |

| 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 |

32.30 36.00 40.00 43.50 47.00 53.50 58.40 59.40 64.90 70.30 75.60 |

244.48 244.48 244.48 244.48 244.48 244.48 244.48 244.48 244.48 244.48 244.48 |

48.07 53.57 59.53 64.73 69.94 79.62 86.91 88.40 96.58 104.62 112.50 |

7.92 8.94 10.03 11.05 11.99 13.84 15.11 15.47 17.07 18.64 20.24 |

PS PS – – – – – – – – – |

– PSLB PSLBE – – – – – – – – |

– PSLB PSLB PLB PLB – – – – – |

– – PLBE PLBE PLBE PLBE PLB – – – – |

– – PLBE PLBE PLBE PLBE PLB – – – – |

– – PLBE PLBE PLBE PLBE PLB P P P P |

– – – PLBE PLBE PLBE PLB – – – – |

– – – – PLBE PLBE PLB – – – – |

| 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 |

32.75 40.50 45.50 51.00 55.50 60.70 65.70 |

273.05 273.05 273.05 273.05 273.05 273.05 273.05 |

48.74 60.27 67.71 75.90 82.59 90.33 97.77 |

7.09 8.89 10.16 11.43 12.57 13.84 15.11 |

PS PS – – – – – |

– PSB PSBE PSBE – – – |

– PSB PSB PSB PSB – – |

– – – PSBE PSBE – – |

– – – PSBE PSBE – – |

– – – PSBE PSBE PSBE PSB |

– – – PSBE PSBE PSBE PSB |

– – – – – PSBE PSB |

| 10-3/4 10-3/4 10-3/4 |

73.20 79.20 85.30 |

273.05 273.05 273.05 |

108.93 117.86 126.94 |

17.07 18.64 20.24 |

– – – |

– – – |

– – – |

– – – |

– – – |

P P P |

– – – |

– – – |

| 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 |

42.00 47.00 54.00 60.00 65.00 71.00 |

298.45 298.45 298.45 298.45 298.45 298.45 |

62.50 69.94 80.36 89.29 96.73 105.66 |

8.46 9.53 11.05 12.42 13.56 14.78 |

PS – – – – – |

– PSB PSB PSB – – |

– PSB PSB PSB – – |

– – – PSB P P |

– – – PSB P P |

– – – PSB P P |

– – – PSB P P |

– – – PSB P P |

| 13-3/8 13-3/8 13-3/8 13-3/8 13-3/8 |

48.00 54.50 61.00 68.00 72.00 |

339.72 339.72 339.72 339.72 339.72 |

71.43 81.10 90.78 101.19 107.15 |

8.38 9.65 10.92 12.19 13.06 |

PS – – – – |

– PSB PSB PSB – |

– PSB PSB PSB – |

– – – PSB PSB |

– – – PSB PSB |

– – – PSB PSB |

– – – PSB PSB |

– – – – PSB |

| 16 16 16 16 |

65.00 75.00 84.00 109.00 |

406.40 406.40 406.40 406.40 |

96.73 111.61 125.01 162.21 |

9.53 11.13 12.57 16.66 |

PS – – – |

– PSB PSB P |

– PSB PSB – |

– – – P |

– – – P |

– – – – |

– – – P |

– – – P |

| 18-5/8 | 87.50 | 473.08 | 130.21 | 11.05 | PS | PSB | PSB | – | – | – | – | – |

| 20 20 20 |

94.00 106.50 133.00 |

508.00 508.00 508.00 |

139.89 158.49 197.93 |

11.13 12.70 16.13 |

PSL – – |

PSLB PSLB PSLB |

PSLB PSLB – |

– – – |

– – – |

– – – |

– – – |

– – – |

| Remarks: P——Plain end;S—Short round thread;L—Long round thread;B—Buttress thread;E—Extreme-line. | ||||||||||||

Note: Other premium connection shall be provided as per customer requirements.